TRANSFORMING

WASTE INTO VALUE

Discover how SECURE has set a new bar for industrial

waste management in North America.

We Got This.

DISCOVER

SECURE

Waste Management and Energy Infrastructure work together to deliver seamless, end-to-end solutions that maximize performance while minimizing environmental impact.

Our fully integrated waste management network combines valuable infrastructure and deep expertise to handle every aspect of industrial waste. This vital service protects people and enables key industries to prosper, now stronger and safer than ever before.

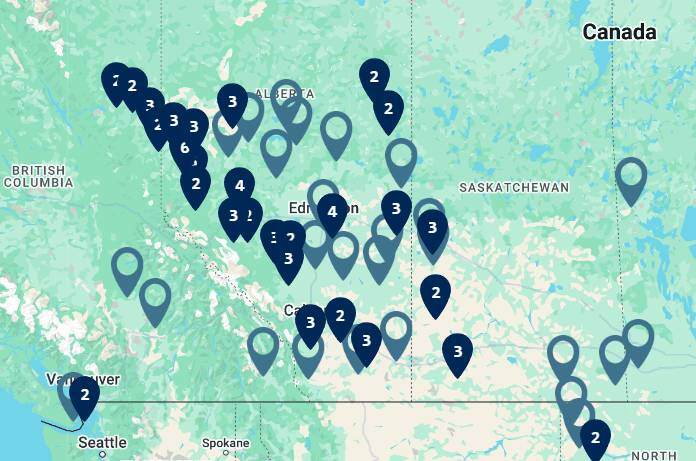

With over 80 facilities and landfills across Canada and the USA, our vast, fully integrated waste management network protects people and helps businesses succeed.

INVESTORS

Leadership in a high-demand category, vital services, critical infrastructure, deep expertise and a lengthy track record of waste management make SECURE a significant growth opportunity.

Careers

MORE THAN

JUST A JOB

You will make a difference here. Join us to do important work that matters, while building a rewarding and successful career.

Facilities & Landfills

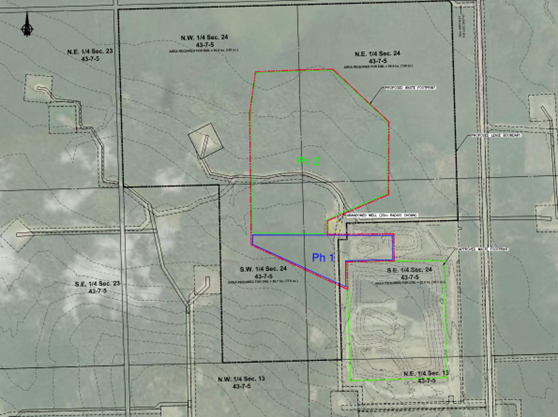

Over 80 strategically located facilities and landfills across North America providing critical energy, environmental and waste management services.

FIND A FACILITY OR LANDFILLSearch our locations to find where SECURE's waste management facilities can transform your waste into value.

SUSTAINABILITY

Sustainability is both the core of our business as well as how we operate. Our customers count on responsible waste management to thrive, respecting all environmental laws and regulations. And we do it well. Our vast integrated network protects people and helps businesses succeed.

.jpg?width=2000&height=1334&name=Kitimat%202024%20Jpegs%20(22).jpg)

RESPECTFUL ENGAGEMENT

SECURE operates within the Traditional Territories and Treaty areas of many Indigenous Communities. We are grateful for the benefits these lands provide all of us. We appreciate the deep-rooted relationship Indigenous Peoples, past and present, have with the land and water.

pARTNERSHIPS AND AGREEMENTS

As our business continues to grow and mature, so will our relationships with our Indigenous partners. Where viable, we aspire to create more impactful and meaningful partnership agreements. Our goal is to support waste management initiatives that align with our corporate community pillars.

ECONOMIC INCLUSION

Since SECURE’s inception in 2007, we have collaborated and built lasting relationships with Indigenous communities and businesses. This commitment can only be fulfilled through respectful engagement and providing opportunities for increased economic participation.

SUSTAINABILITY REPORT

This report includes information related to SECURE's achievements, activities, goals, commitments and plans, as well as statements about the environmental benefits and climate-related effects of waste management by our operations, services and business.

READ THE 2023 SUSTAINABILITY REPORT